CAD

I work with modern parametric 3D CAD systems such as CATIA, SolidWorks and Fusion 360 to develop components, assemblies and the corresponding technical documentation. Many designs are based on solid calculations that ensure a functional and reliable design. I frequently integrate components such as sensors, actuators and other system elements to create holistic technical solutions. A clear data structure and consistent modelling enable efficient adjustments and ensure smooth implementation – from prototypes to production-ready designs.

Manufacturing process

Cost-effective design begins with an understanding of manufacturing processes. From the outset, I take into account tolerances, fits, and the requirements of various methods: milling, turning, drilling, grinding, as well as modern techniques such as 3D printing, metal spinning, or the processing of CFRP/GFRP components. Depending on the project requirements, forming techniques, welded joints, or sawing processes are also incorporated.

Materials

I design with a wide range of metals – especially aluminum and steels – taking into account heat treatments and tempering. Plastics, composite components, and the associated manufacturing processes are also part of my expertise, particularly for lightweight or functionally integrated applications. Additionally, I plan surface treatments such as anodizing, bluing, electroplating, powder coating, or painting to specifically address corrosion protection, wear resistance, or visual requirements.

Dimensioning of components

I support you in the targeted selection and integration of technical components such as actuators, sensors, standard parts, guides, connection technology, or energy chains. This also includes systems like compressed air treatment, springs & dampers, or gearbox solutions. Upon request, I also provide consulting for the supplier selection of standard and special components.

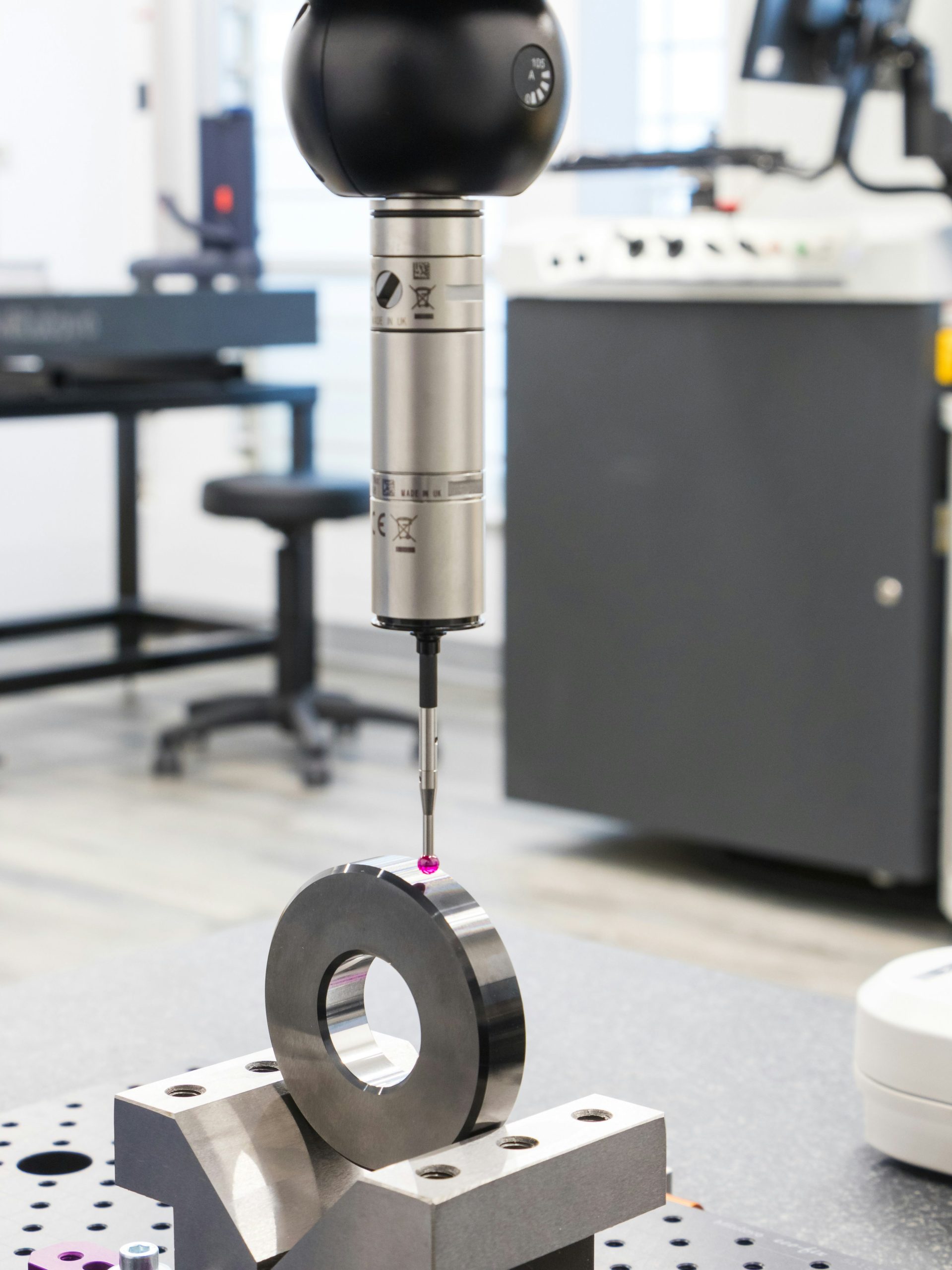

Sensors

I plan and integrate a wide range of components: inductive and capacitive sensors, cylinder switches, position and pressure sensors, energy measurement systems, and touch probes, as well as vibration sensors or optical sensors such as reflective photoelectric sensors, light sensors, lasers, color sensors, and fiber optic sensors.

Actuators

I design drive solutions with pneumatic and electric actuators, such as pneumatic cylinders, swivel units, servo motors, stepper motors, or linear axes. The design and integration of grippers, stoppers, mechanical or vacuum grippers is also customized according to application and environment.

Industrial robots

I develop mechanical solutions around the use of industrial robots, especially the design of grippers (end effectors), robot bases, and complete handling systems. When designing robotic components, I use tools such as KUKA Load to analyze payload capacities and motion profiles early on and adjust the design accordingly. In collaborative applications, I rely on technologies like Airskin to enable safe and at the same time high-performance interactions between humans and robots.

Calculations

To ensure the reliability and safety of your designs, I perform technical calculations – from the dimensioning of mechanical manufactured parts and purchased components, through the lifetime calculation of components, design of springs and dampers, to the moment of inertia calculation of robotic end effectors.

Technical documentation

I create comprehensive technical documentation – from manufacturing and assembly drawings to bills of materials (BOM), assembly instructions, risk assessments, and support with CE conformity declarations. All relevant standards are taken into account to ensure smooth assembly and commissioning.

Planning & process optimization

In addition to pure design, I also support you with production and assembly planning as well as interface coordination. With solid knowledge in project and quality management and automation (e.g., through cycle time diagrams), processes can be specifically optimized.